What is Roofing Underlayment & Why is it Needed?

Published on Friday August 16, 2024

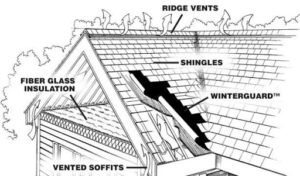

Before your roof is covered with shingles, a layer of material called roofing underlayment is placed on the roof deck. This layer provides extra protection from rain and helps keep your home cozy and dry. Underlayments are usually made of asphalt-saturated felt, rubberized asphalt, or synthetic material. They’re generally not visible once the roof is complete, but they play key roles in keeping your home safe and comfortable.

Read on to learn more about this important addition to your roof and the different roof underlayment types available.

What Are The Types of Roofing Underlayment?

There are three main types of roof underlayment used under roof materials:

- Asphalt-saturated felt

- Non-bitumen synthetic underlayment (also known as “synthetic underlayment”).

- Rubberized asphalt underlayment

Note that asphalt-saturated felt and synthetic underlayments are water-resistant, meaning they can handle light rain but, after many years, may eventually let water through. Rubberized asphalt underlayment is waterproof, meaning it’s completely impervious to water, even after years of hard rain. We’ll go into greater detail about water-resistant vs. waterproof later.

Asphalt-Saturated Felt

Asphalt-saturated felt was the go-to roofing underlayment until the turn of the 21st century when synthetic underlayments became popular. It’s still a great shingle underlayment, though. This type of underlayment is commonly referred to as “felt paper” or “tar paper” and is made from varying blends of cellulose (natural plant fibers), polyester, bitumen, or asphalt.

This underlayment typically has a flexible base layer saturated with asphalt for water resistance and is applied across the entire roof deck.

The advantage of asphalt-saturated felt is that it comes in different thicknesses with varying resistance levels to damage and weather exposure. Thirty-pound asphalt-saturated felt, for example, can actually protect the roof longer if exposed to hail, wind, rain, and snow. It’s less expensive than many other materials, provides a sound seepage barrier, and can easily be installed using standard tools.

The disadvantage is primarily its weight: it can be heavy, especially when it’s layered enough to be adequately effective in harsher climates. It’s also more difficult to install because it’s heavier than other options. When exposed to cold, it can wrinkle and crack. Asphalt-saturated roofing felt underlayment contains volatile compounds, which can dissipate when exposed to heat. This can cause the underlayment to absorb more moisture and break apart.

Synthetic Underlayment

Most roofing professionals today prefer synthetic underlayment (aka non-bitumen synthetic underlayment) due to its outstanding tear resistance and stability. High-quality synthetic underlayment also has scrim reinforcement for added slip resistance, even when wet.

Synthetic underlayment is designed for application across the entire roof deck and is sometimes used along with additional waterproof products. It’s a lightweight, effective water barrier. It’s also more tear-resistant when exposed to high winds and doesn’t absorb moisture, so it resists mold and fungal growth. It will maintain its integrity even when exposed to the cold and doesn’t wear down as quickly as others.

The main disadvantage of synthetic underlayment is that it tends to be more expensive than asphalt-saturated felt and requires specialized tools and skills to install correctly.

Rubberized Asphalt

Rubberized asphalt is more expensive than other types of roofing underlayment because it contains higher percentages of asphalt and rubber polymers, making it fully waterproof – not just water-resistant.

Rubberized asphalt underlayment often has a sticky back with a protective membrane that’s removed prior to installation. This special backing creates a waterproof seal between the underlayment and a clean roof deck. The underlayment then protects the edge of the roof deck from water damage and is much more heat- and cold-resistant than asphalt-saturated felt.

If your roofer needs to wait before installing your primary roof covering, rubberized asphalt underlayment can be exposed to weather elements for up to 180 days without severe effects.

However, a significant disadvantage of rubberized asphalt is the cost. Although you’ll enjoy the benefits of this material for years to come, it will be a higher upfront expense.

Water-Resistant Vs. Waterproof Roofing Underlayment

Water-resistant underlayment is enough for the surfaces of most roofs. It provides solid protection for your roof during and after installation. Even without the added protection of shingles, a superior water-resistant roofing underlayment can withstand some seriously extreme weather.

However, there are regions where fully waterproof roofing underlayment should be used. Waterproof underlayment is recommended for roofs in areas prone to high winds or ice damming.

Even in regions without severe weather, waterproof roofing underlayment should be used for some sections of the roof:

- Eaves

- Valleys

- Protrusions (chimneys, vent pipes, skylights, etc.)

- Surfaces of low-slope roofs

Pros and Cons of Roof Underlayment

Roofing underlayment is a good idea but not 100 percent necessary. It’s designed as extra protection for your roof. If the top layer of your roofing material springs a leak, a roof underlayment keeps your roof decking dry and safe. Without a roofing underlayment, rain and other bad weather can seep into your roof deck and cause severe problems like rot, mildew, and mold.

If you’re hoping to install the most budget-friendly roof, skipping the underlayment will help keep your upfront costs down. However, for the safest, most water-resistant roof or to extend the lifespan of your roof, be sure to include the underlayment in the installation.

Pros of Roofing Underlayment

- Extra protection against weather and storms

- Water-resistant and waterproof options

- Mold and rot prevention

- Leak protection

Cons of Roofing Underlayment

- Expensive

- Harder to install

- Some roof underlayments lose their effectiveness after years of UV exposure

How to Choose the Right Roofing Underlayment

The right roofing underlayment should work with your roof type. Metal roofs, for example, do well with a synthetic underlayment that has higher heat resistance since the metal can trap more heat. A traditional asphalt shingle roof, on the other hand, will do best with a roofing felt underlayment.

It’s also important to consider the typical climate where you live. If you live in a hotter climate, you want to choose an underlayment that can handle the heat, whereas if you live in a climate that is frequently snowy, you’ll need something heavy-duty.

Lastly, you’ll want to consider the price when choosing your underlayment. Decide on your budget, and then you can more easily see what options are available to you.

Get Expert Advice With Long Roofing

Roofing underlayment extends the life of your roof and keeps your home safer and moisture-free. Invest in solid roofing underlayment now and prevent costly repairs from major damage in the future.

The experts at Long Roofing are happy to answer any questions you have about roofing underlayment and financing options. Contact us today to find out more!